Design and modeling – types of shoe uppers – Tips for Shoe Production

Spring mode to highlight parts of the sheet

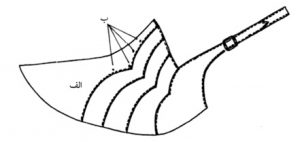

The following design is suitable for various combinations of raw material design and modeling. Part A is the most technically important part that must have a precise cut in the design and modeling and be springy in the folded parts. To achieve such a situation, several pivot points (B) must be used.

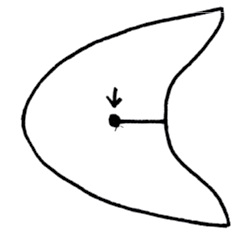

If the shoe has a long sheet with a sheepskin lining, a hole should be made in the leather lining of the sheet and then a hole should be made in the end. The liner often ruptures at the end of this gap. In designing and modeling this, to prevent this rupture, a punch pipe is placed at the end of the gap (the place mentioned by the arrow).

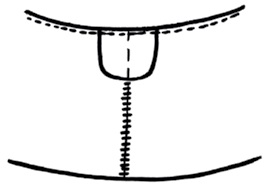

Creating wrinkles or uirecreases reqs its own technical method. They often use thin strips of elastic textiles in their shoes. But another method can be used for design and modeling and elastic textiles can be installed on a narrow and cut section.

After assembling the desired part, the adhesive tape should be glued on the upper side and the elastic textiles should be removed from the lower part and the adhesive tape should be glued to keep the folds and the adhesive tape should be pulled on the upper side.

If the protective part of the back seam of the shoe has an angled shape, and especially if the leather on the upper of the shoe is narrow, its corners will be easily damaged. Therefore, it is better that the back seam protector of the shoe is facing down.

If we want to fold the paper pattern in a linear direction, we can moisten the middle a little so that it bends better.

It is difficult to understand why many designers and pattern cutters still combine the design of the interior and exterior. We do not mean the joint area here, but the difference in the pattern design of the ankle and the back of the foot.

Of course, we know that in this part, there is a significant difference between the inner and outer part of the mold.

If the sheet does not have a special extra space on the inside, it will be very tight from the water, and in cases where there is very little space, longitudinal wrinkles will be created and it will be more difficult to mold the side part. The same goes for the back seam at the heel, which should have more space at the top than the back curve.

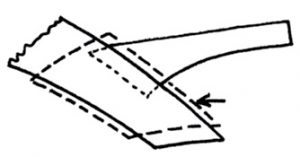

In the figure above, the hash section of the tab shows approximately how much extra space is needed in this section. The heel line also refers to the inside of the pattern.

The beginning and end of moccasin seams should be sewn. This is usually done by hand. If the moccasin has a derby type back, this embroidered suture can replace the back seam. The hand part should also be drilled to make the embroidered stitches decorative.

In lined sandals that sew the heel strap to the sheet, the interior design and modeling is not very pleasant because the sewing chair in the heel strap loosens and protrudes. It is better to have a liner in this part so that there is a soft surface inside. The arrow shows the liner section.

From “Tips for shoe production, Volume 1: Design (2nd Edition)”

Author: A.Wilhelm