A special feature of the heel structure of shoes is that they can be made in pairs, because each layer of them must be exactly the same height by the shoemaker in both pairs of shoes. The shoemaker measures each heel separately after making it. If the lifter is too thick in one of them, reduce its size with a hammer and razor so that the other heel size is the same in the other shoelace. After making both heels, the shoemaker then re-measures their height to make sure they are exactly the same.

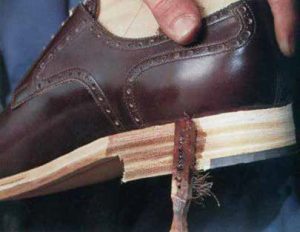

The next step that requires the most care is to shape the outside of the heels. The shoemaker cuts the heels around with a sharp knife so that when the person wearing the shoe starts walking, the angle of the inside of the ankle is 90 degrees with the ground and the outside of the heel is from the ground to the ground. Be inclined inside.

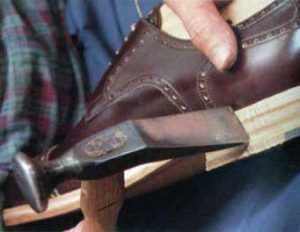

The shoemakers hammer out the heels of the shoes to make the material compact and hard. The shoemaker also keeps the surfaces of the heels moist with a wet brush and presses the leather edges tightly with the angled side of the hammer head and makes short blows to it.

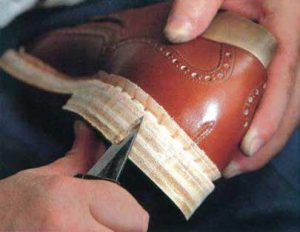

Each time the shoe attaches another heel to the sole of the shoe, it cuts off the extra parts to match the previous heel. In this photo, only the end part of the soles and the bottom of the rubber band should be added to complete the heel of the shoe.

Wet leather is softer than dry leather, and this is so that if the layers of leather are moistened with water from the beginning, the shoe can be more easily peeled off with a knife. The heel nutrition of the shoes is also curved and should be taken into account when measuring. In addition, the wet outer part of the heel is hammered and compressed.