degradability:The growing desire of consumers for more durable products, along with the government’s demand for more environmentally friendly products, has led the leather industry to adopt and use alternative tanning methods and processes that make leather more environmentally friendly. The end of its life cycle breaks down faster. This issue is evolving so that degradability time recently the Inscope has rapidly and effectively developed a special technology to evaluate the degradability of leather

Based on the international standard ISO 20136, this technology makes it possible to accelerate such evaluation methods to determine the degradability characteristics of materials in a period of 30 days that can be found in the natural environment. It takes years for them to disappear. quantitative leather

For all leather industries, sustainability and durability are key. In fact, the impact they have on the environment is clearly the main concern of dynamic, reputable and progressive brands. Today, a major challenge for the leather industry, especially the brave leather industry, is to develop innovative and resource-efficient methods that either prevent or reduce the use of water, energy, hazardous chemicals and waste. degradability quantitative leather

This need led to the fact that the market is changing. This is due to the fact that on the one hand, the awareness of consumers and brands to use resources that are morally correct is increasing, and on the other hand, it is related to the invention and implementation of European legislation for the use of certain chemicals.degradability

In addition, the leather industry needs to use the issue of environmental impact as a way to advance the competitive market, and these changes can be seen as business opportunities. As a result, the industry is looking for a way to promote and upgrade more durable leather products based on greener tanning methods, improving and modifying degradability during the useful life of leather along with other sustainable approaches.quantitative leather

For this purpose, new test methods are needed to calculate the degradation time of leather in the environment in a short and cost-effective period. With the implementation of recent alternative methods, as it seems that a long test time, high costs and even field tests are required, the test time can take years. degradability

For this purpose, in 2017, a section related to determining the time of degradation of leather by microorganisms was launched by the World Standards Organization ISO 20136. The basis of this standard method is based on the incoscope, whose system is fully automated and based on internal technology, which allows the ready-made leather to be evaluated quickly and efficiently in terms of quality. quantitative leather

The system uses a secondary ISO 20136 methods that uses infrared radiation to show how aerobic microorganisms degrade leather and produce carbon dioxide-like quality. Software specific to this method was also designed to simulate pressure, temperature, and air circulation. degradability

Simultaneous evaluation of four pairs of samples is possible, which includes positive and negative controls required for validation under this standard. For positive control, i.e. pure collagen, to be invoked, at least 70% degradation must occur over a 30-day period. For negative control, inoculation must be completely in accordance with environmental samples. degradability

In this way, the system can determine that the carbon dioxide produced is solely the result of biodegradation for that sample to calculate the percentage of biodegradation. To confirm the laboratory results performed according to this standard, field tests were performed with the same similar leather samples. degradability time

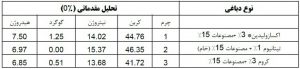

These tests were performed by the Spanish tanning site Segobe S. L in a biological tank. At the site where the laboratory test results were obtained, three types of tanned leather were evaluated by the three methods of oxazolidine, titanium and chromium, respectively. The following is a table of information obtained from each of these experiments

| Type of tannery | Preliminary analysis (0%) | ||||

| Leather | Carbon | Nitrogen | Sulfur | Hydrogen | |

| Oxazolidine (3%) + Artifacts (15%) | 1 | 44.76 | 14.02 | 1.25 | 7.50 |

| Titanium (1%) + Raw Artifacts (15%) | 2 | 46.35 | 15.37 | 0.00 | 6.97 |

| Chrome (3%) + Artifacts (15%) | 3 | 41.72 | 13.68 | 0.51 | 6.85 |

Oxazolidine is a chemical compound with the chemical formula C3H7NO. Its molar mass is 0938.73 grams per mole. Oxazolidine is a five-membered ring consisting of three carbons, one nitrogen and one oxygen. Oxygen and NH are in positions 1 and 3, respectively. In oxazolidine derivatives, there is a carbon between oxygen and nitrogen or it is an isoxazolidine. All carbons are reduced compared to oxazole and oxazoline oxazolidine. Some of their derivatives, 2-Oxazolidone, are used as anticoagulants. degradability time