Horween Leather Company, a family business, has been in the leather business for over 100 years. The company has excellent relationships with several shoe brands that use the company’s leathers to make their products as luxurious as possible.

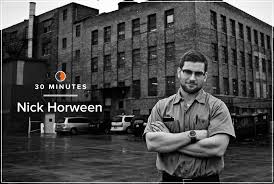

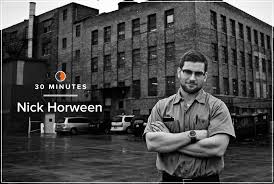

Nick Horween is the fifth generation of his family to work for the Horween leather company since taking office in 2008. His father, Arnold Skip Horween, has headed the collection since 2003, and together they run one of the oldest tanneries in the United States.

The company was founded in 1905 by Isador Horween, who immigrated to the United States from his native Ukraine in 1893. From 1893 to 1905 he worked in various tanneries in Chicago and then decided to establish his own tannery, which is now the last tannery in the city.

The company was able to survive in a period when the number of tanneries in the United States was rapidly declining. Of the more than 250 centers in 1978, there are now less than 12. This company is one of the few companies that process leather from raw leather to final leather. He mainly processes cow skin (which accounts for 85% of total production) and horse skin. Of course, a small amount of calfskin is also used in the work of this company.

Nick Horween is considered one of the most trusted leather manufacturing companies for a number of brands due to his commitment to manual mechanical production and his refusal to cut leather corners. This is in such a way that the employees of this company, most of whom have worked in this center all their lives, follow the same standards that have been maintained for more than 100 years.

Although leathers are still made with the intervention of hands and using traditional methods that have been preserved for generations, modern machines can also be seen in this center to keep up with the changes in the industry. The company has a waste processing plant that fully complies with the standards of the US Environmental Protection Agency.

By choosing this center by several sports shoe brands to add a luxurious element to its shoe designs, the company has proven to be a very important market for shoe companies. New Blanc, Reebok, and Adidas are among the brands that use the leather produced by this center. Nick Horween says his company has been working with the New Blanc brand for about five years. According to him, this brand uses different leathers of this factory according to the color and design of its desired shoes. This brand orders its desired leathers based on its needs and then, using its skill, makes the necessary and useful modifications on these leathers.

In August last year, New Blanc announced that it had used the company’s leathers in 1,300 and 998 separate models of its shoes. In 1300 models, neutral shades of brown have been used and in 998 models, black leather has been used on the surface. In addition to leather, leather is also used in heels, shoe soles and insoles.

Nick Horween says he appreciates the work that the New Blanc brand has done to present its designs on the factory leathers. He believes that consumers fully understand the high quality of the products and the thinking behind their design. He stated that according to the agreements he has with this company, he cannot say what kind of leather this company uses, but here he declares that Cordovan leather is not one of those leathers.

There are only a limited number of leather manufacturers in the world that produce Cordovan oyster genuine leather, which has been chosen for this leather because of an area in Spain called Cordoba. The Argentine company Rosinante, the British company Clayton, the Japanese company Shinki-Hikaku and this factory are the only centers for the production of this type of leather in the world. This leather is made from horses bred in the area mentioned. This leather is also made from the skin on both sides of each horse’s buttocks, which is hardly enough to make a pair of shoes. In addition, the horse’s oval shells are tanned and take six months to turn into leather. As a result, a very beautiful and durable leather is produced, the quality of which increases over time.

Nick Horween talks about what leather brings with it in the design of sneakers, about adding beauty and durability to shoes. “Unlike some sneakers, leather sneakers add to the beauty of the wearer over time,” he says. Reebok has recently announced that it uses Horween leather in its classic and luxury leather collection. These designs are available with a black or oiled brown leather upper with boot details. Apparently, this shoe has a bit of antiquity in its appearance. Reebok has partnered with the company in its classic Borgue leather collection, producing shoes in burgundy and navy blue. Last year, Reebok and Adidas used the factory leather in the classic Stan Smith Silhouette collection. In this collection, a one-piece leather upper is used.

According to leather makers, Essex vegetable leather gets more beautiful over time. Wolverine sports brand launches customization system, allowing its customers to design their own 1000 mile boots. Products with a history of 100 years, which are produced with leather upholstery from this factory.

The center’s Chromexcel leather was invented about 100 years ago, another raw material often used in shoes. The natural folds and creases of this leather give it a rough and uneven appearance and can achieve a high degree of gloss in the final finish. During the production of this product, which is 28 days, this leather is processed 90 times separately. First, it is tanned with chrome and then it is tanned for the second time with heavy plant materials such as a combination of tree extracts and natural materials for the second time. The result of this two-step tanning process is soft leather with a rugged appearance that retains its natural color. Easy molding of this leather makes it ideal for shoe production.

Nick Horween describes shoes as an important part of his business. The types of leathers produced by this factory are purchased by various reputable brands. He considers himself one of the few successful leather makers left in the United States. According to Mr. Horween, the company is always looking to develop and discover new opportunities and anticipates increasing cooperation with shoe brands in the future.

Dalir Leather Industries with more than half a century of experience in household business in the leather industry (managed by Mr. Hassanzadeh Dalir) and a pioneer in technology and promotion of leather in the Iranian leather industry seeks to increase the quality and production of its leather products. In Dalir Leather Industries, we hope to proudly continue our quality production by gaining a lot of experience in global leather production.